Virtual validation in real time – precise simulation for complex production systems.

Simulation makes it possible to digitally map complex production processes realistically – way ahead real systems are created. We use this method to visualize dynamic interactions, bottlenecks and performance limits of your processes. This allows us to evaluate alternatives, minimize risks and identify efficiency potential – quickly, transparently and measurably.

Digital Models for real Questioning:

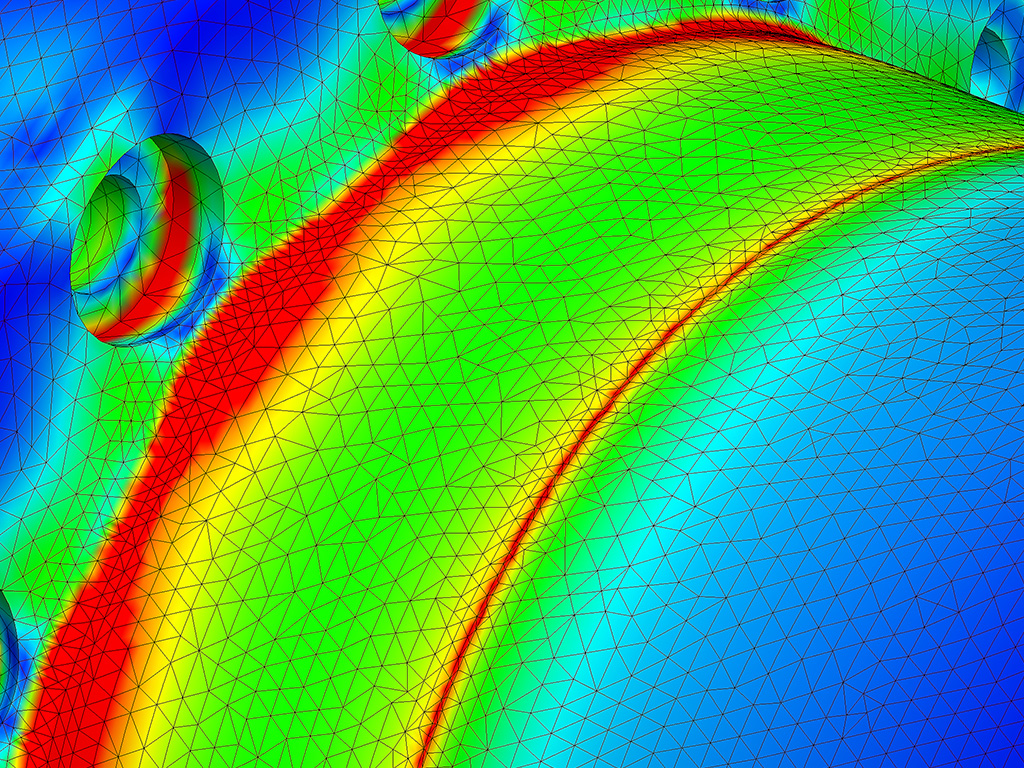

We create detailed simulation models of your manufacturing processes and logistics systems. Whether material flow, resource utilization or component and process design – data-based modeling creates a digital representation of your real-world processes.

Developing and Comparing Scenarios:

Which component design and casting system meets the quality and cost-effectiveness requirements? What impact will a new line layout have? What capacity utilization is realistic? Using alphanumeric simulation, we test variants and future scenarios under realistic conditions – without wasting time or incurring investment risks.

Securing Planning, Strengthening Decisions:

Simulation provides reliable analyses and key performance indicators for manufacturability, design, throughput, utilization, cycle time and susceptibility to failure.

This enables us to make reliable decisions – e.g. regarding component and tool design, layout changes, automation measures and implementations or capacity expansion.

Making Challenges and Complexities Visible and Manageable:

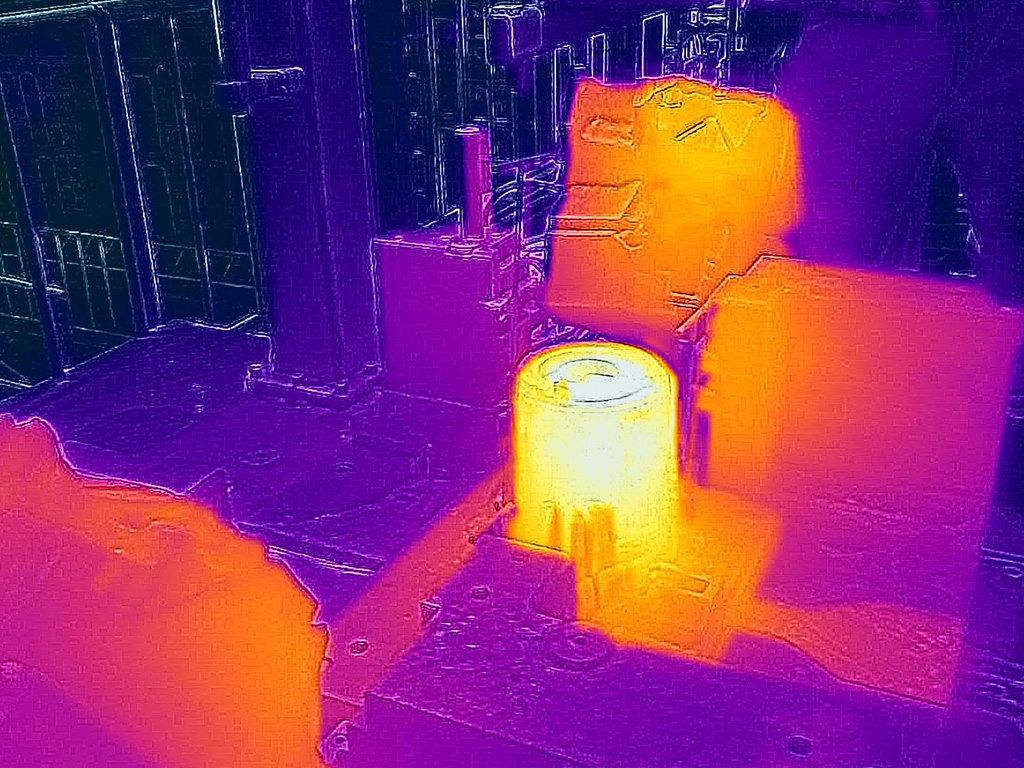

With our alphanumeric mold filling simulation, we offer the ability to visualize and optimize temperature distribution and transitions, pressure distribution, mold filling, turbulence, convection, mold temperature control, exothermic masses, chills, hot spots and mold wear.

The solidification simulation depicts shrinkage-induced porosity, solidification and cooling behavior, stresses, distortion and microstructure, among other factors, and offers the opportunity for optimization in these areas as well.

The core shooting and curing simulation demonstrates the filling and curing process by displaying pressure, speeds, sand/air ratio, fill level, and density, as well as tool and gas temperatures.

Finally, there is the heat treatment simulation, which makes the annealing of castings transparent by displaying temperatures.

From Simulation to Implementation:

We support you not only with modeling and evaluation, but also with translating simulation results into reality – as part of your process design and optimization, plant structure planning or investment preparation.

Our simulation tools provide the best foundation for a “first-time right” strategy, continuous process improvement and optimization and development of castings and foundry processes.

We increase your quality, efficiency and profitability in all areas of the foundry industry. Whether sand, permanent mold, precision, or low-pressure casting, or HPDC, we are at home in all casting materials.

We support you from the first idea to final implementation

with technical know-how, planning experience and clear vision.

Are you planning a new plant or production site?

We support you from the initial idea to commissioning.

Submit your project request now!

Deutsch

Deutsch