Modernization and expansion of your cast iron production – during ongoing operations, safe and efficient.

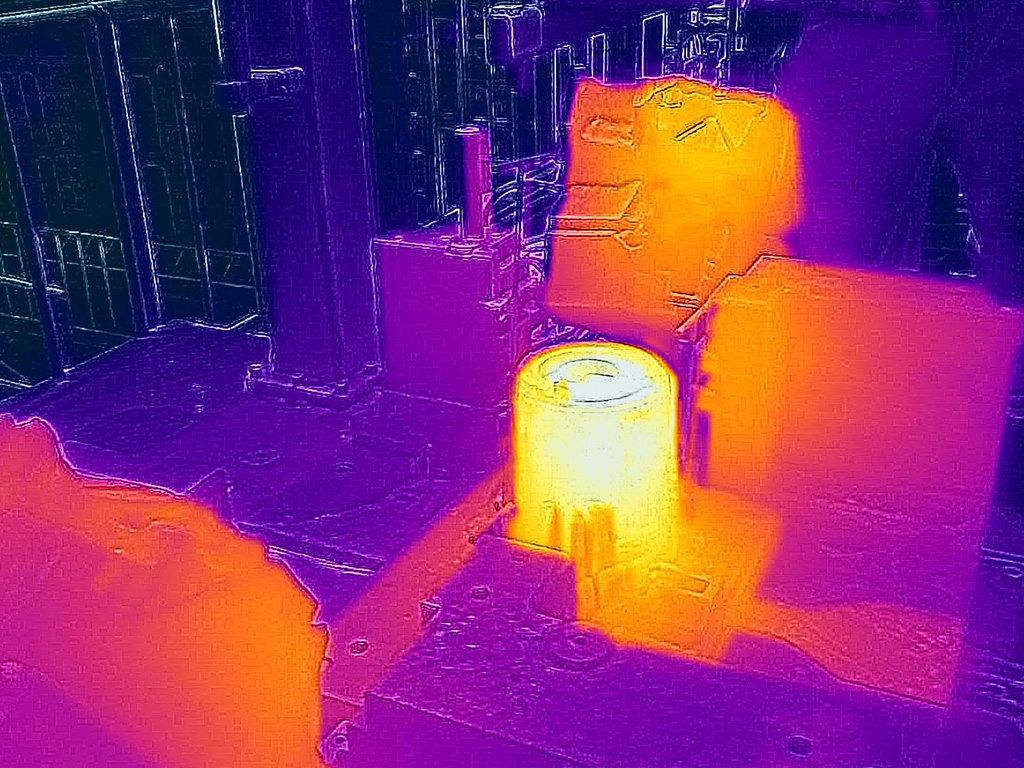

Downtime is not an option in the foundry industry. That’s why at Krapohl-Wirth we develop customized brownfield solutions for cast iron plant operators – from precise assessments and planning to implementation during ongoing production. Whether furnace modifications, cooling technology optimization, or integration of new units: we combine construction expertise with deep understanding of foundry processes.

Our Services for Foundries:

Modernization

of Melting Plants

Efficient adaptation and expansion of existing melting units for higher performance and energy savings.

Optimization of

Cooling Water Circuits

Modification and control of thermal systems for stable production and reduced downtime.

Structural Adaptation to

High-Temperature Zones

Structural reinforcements and heat-resistant linings in critical plant areas.

Integration of

New Filtration Systems

Retrofitting modern filtration technology to reduce emissions and comply with legal requirements.

Modifications During

Ongoing Operations

Reliable construction coordination with minimal disruption to production processes.

Safety and Fire

Protection Solutions

Planning and implementation of customized protection systems for people, equipment, and buildings.

Dipl.-Ing. Wolfgang Wirth

Executive Officer of Krapohl-Wirth Consulting Group

Whether iron, aluminum, or non-ferrous metals – his name is associated with the demanding field of “design.” He optimizes operational processes, KPIs, budgets, times, and scrap rates. Thanks to his extensive leadership experience, he is able to lead operational companies back to profitability in a short period of time.

The foundry engineer has held senior positions at renowned international foundry companies since 1985, has worked in consulting since 2000, and is one of the founders of the group. A multilingual doer and global player, he has worked in Europe, Latin America, Asia, Australia, and South Africa.

Education:

Degree in foundry engineering from the University of Friedberg.

Dipl.-Ing. (FH) Carsten Engelke

VP Engineering & Partner

Planning and engineering specialist, responsible for managing international projects with a global approach. Leads international projects on behalf of OEMs, TIER-1, and TIER-2 suppliers. Stands for “structured, innovative planning and implementation.”

18 years of experience in the automotive industry in international companies in factory planning, engineering, and supplier management (cast parts) in the TIER-1 sector. Partner of Krapohl-Wirth Consulting GmbH as of April 2024.

Education:

Dipl. Ing. (FH) in mechanical engineering from Braunschweig/Wolfenbüttel University of Applied Sciences, distance learning in business administration.

Dipl.-Ing. (FH) Jan-Christoph Schwarck

CEO & Partner

Foundry and management generalist, responsible for managing large-scale international and strategic projects in Europe, North America, and India. From idea to market launch, his motto is “Make it work.” He is our all-rounder, overseeing projects from blueprint to series production.

16 years of foundry and automotive experience in national and international companies. Joined KW Group in 2022, CEO and Partner of Krapohl-Wirth Consulting GmbH since 2024.

Education: Dipl. Ing. (FH) in mechanical engineering from Lübeck University of Applied Sciences, specializing in material properties.

.

Planning to rebuild or expand your foundry?

Talk to our experts for brownfield projects in the casting sector.

Request a consultation now – without obligation!

Deutsch

Deutsch