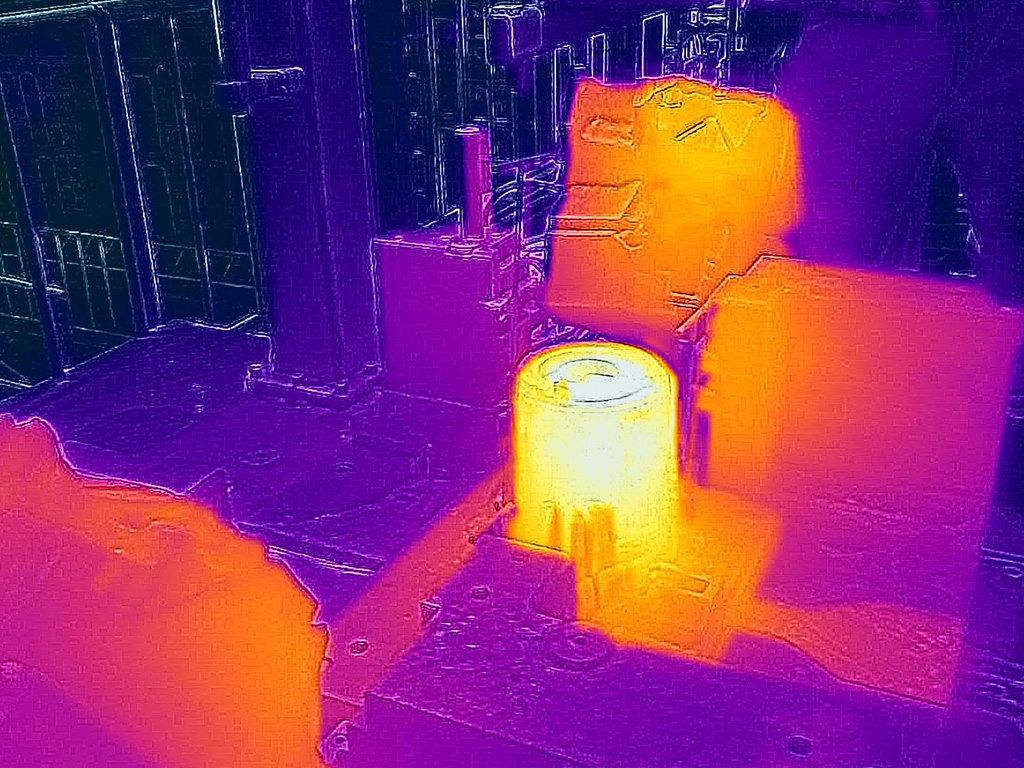

Construction of new foundries – efficiently planned, robustly built, designed for the future.

From greenfield to a production-ready foundry: With Krapohl-Wirth, you realize demanding greenfield projects in cast iron manufacturing from a single source. We understand the complex requirements of thermal processes – and translate this knowledge into well-conceived building designs, robust infrastructures, and on-time implementations. For maximum efficiency, operational safety, and long-term viability.

Our Services in the Greenfield Sector:

Site Development

and Preparation

Planning and implementation of all infrastructural prerequisites for the successful operation of new foundry sites.

Turnkey Plant

Construction

Construction of complete foundry infrastructure – from shell construction to handover to operations.

Foundry-Specific

Building Design

Temperature-, load-, and process-optimized architecture for sustainable production environments.

Technical Centers

and Utility Systems

Installation of central energy, water, and air systems – intelligently networked and maintenance-friendly.

Permit Management

and Project Control

Support through all regulatory procedures and transparent management of each construction phase.

Sustainability and

Future Security

Integration of modern energy and environmental standards for a resource-efficient plant.

Dipl.-Ing. (FH) Jan-Christoph Schwarck

CEO & Partner

Foundry and management generalist, responsible for managing large-scale international and strategic projects in Europe, North America, and India. From idea to market launch, his motto is “Make it work.” He is our all-rounder, overseeing projects from blueprint to series production.

16 years of foundry and automotive experience in national and international companies. Joined KW Group in 2022, CEO and Partner of Krapohl-Wirth Consulting GmbH since 2024.

Education: Dipl. Ing. (FH) in mechanical engineering from Lübeck University of Applied Sciences, specializing in material properties.

Dipl.-Ing. (FH) Carsten Engelke

VP Engineering & Partner

Planning and engineering specialist, responsible for managing international projects with a global approach. Leads international projects on behalf of OEMs, TIER-1, and TIER-2 suppliers. Stands for “structured, innovative planning and implementation.”

18 years of experience in the automotive industry in international companies in factory planning, engineering, and supplier management (cast parts) in the TIER-1 sector. Partner of Krapohl-Wirth Consulting GmbH as of April 2024.

Education:

Dipl. Ing. (FH) in mechanical engineering from Braunschweig/Wolfenbüttel University of Applied Sciences, distance learning in business administration.

.

Are you planning a new plant or production site?

We support you from the initial idea to commissioning.

Submit your project request now!

Deutsch

Deutsch